2012 Team Status

US Army PEO STRI High School Engineering Internship

-

Preparing for the Internship:

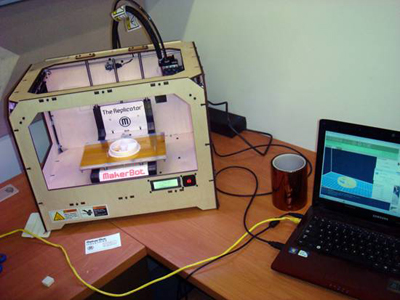

Fri June 1 2012 : Makerbot Install Start

We were fortune to have Mr Maxwell Greenspan and Mr Hassan Siddiqui helping us install the MakerBot and the CAD software needed to implement the models and prototype them.Mr Maxwell Greenspan

UCF - Junior year Mechanical Engineer

Interning at EarthRise Inc

MakerBot ExpertMr Hassan Siddiqui

University High School Graduate (Going to UCF in the Fall) Completed the PEO STRI High School Engineering Internship last year CAD Expert1. We successfully installed the hardware and drivers for the MakerBot prototypemachine.

2. We successfully installed and implemented the CAD software needed for the model prototype.

3. We successfully correlated the dimensions used in the CAD software (Blender)with the MakerBot Replicators software. We verified that the dimensions used for the CAD model was actually being produced by the MakerBot.

4. We produced simple models last week, but when we were producing larger more complex models we observed a calibration issue with our set up. Per Mr Greenspan,this is normal when first setting up the MakerBot. By the nature of this prototyping process, we would have to find the best temperature range, speed and height control for our MakerBot. Due to our limited time frame we could not complete the calibration and verification process.Attached are some pictures from our effort.

Path ahead:

Wed 6 June at 2:30

We will have our follow up meeting to refine the calibration of the MakerBot.

We will verify the calibration by producing the bigger and complex models. -

Wed 6 June: Makerbot Install Completed

Per our plan:

We had our follow up meeting on Wed 6 June to refine the calibration of the MakerBot.

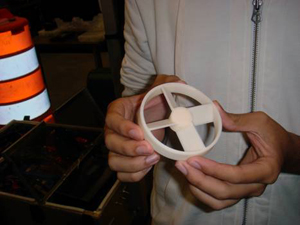

We successfully verify the calibration by producing the bigger and complex models.Attached are some pictures of the models we made.

We made a small PEO STRI lettering.

We made a model of a simple propeller with 3 inch diameter and .5 inch height.

-

Start of the Internship:

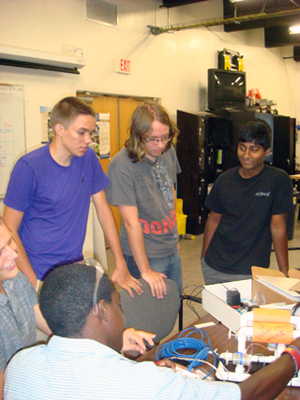

Wed June 20 2012: First Engineering Session of the InternshipThe engineering student all did an awesome job!

The student teams are all ahead of schedule regarding the building of the Sea Perch.The students were divided into 3 teams.

Team Deep Blue:

Hamza Siddiqui, University High School

Zachary Blumer, Timber Creek High School

Michael Thomas, Timber Creek High School

Austen DeGrenier, Timber Creek High School

Tristan Trinh, East River High School -

Team YOLO:

Simeon Sudduth, Lyman High School

Brian Casel, Lyman High School

J.D. Arthur, Lyman High School

Kyle Fern, Lyman High School

Benjamin Manipadam, Lyman High SchoolTeam Girl Power:

Jessica Schneider, Lyman High School

Alex Yinger, Lyman High School

Kaitlyn Evans, Lyman High School

Biumalyn Samson, Lyman High SchoolThe students will start planning for the propeller design.

Develop the CAD model in any application you are comfortable using.

Bring or e-mail the model in STL file format.

I was told today by the students that school will star the week of Aug 13.

So we will change the meeting sessions for the month of August to:

8/3 Fri would work well for the implementing meeting 8/10 Fri would be the final testing and race in the pool.6/29 Fri for the SeaPerch completion and start of design planning

-

Fri June 29 2012: Complete the SeaPerch

All 3 teams successfully completed the building of their SeaPerch.

We verified some of the design limitations wehave to work with:

1. MakerBot is limited with the large angle supports with the designs. The propellers need to have a flat base for fabrication. This was verified using 2 of the designs the teams created.

2. The first concept design for the propeller was verified in the pond next to P2 building. The results showed that the bigger propeller design was too heavy for the SeaPerch motors. We will need to apply techniques to lighten the propeller design.

Tasks for next engineering session:

1. Review the Internship notes - How it Works (it's on the web site in the curriculum section)

2. Identify the wiring modifications needed to the SeaPerch control box so that power would be supplied to the "Brown" wire set for SeaPerch enhancements.

3. Send in your propeller designs for evaluation and guidance.

We also were very fortunate today for having Ms Traci Jones, Assistant Program Executive Officer for Project Support (APEO PS) at US Army PEO STRI, stop by and talk to the internship students. She kindly shared her motivation for career excellence with the students.

Special thanks to Ms Marianne Paulsen and Mr Charles Tucker for helping us with the completion of the SeaPerch.

-

Fri July 20 2012: Verified the SeaPerch propeller designs

-

Team YOLO and Team DeepBlue propeller designs were verified in the pond next to P2 building. The results showed that there was an improvement with the propeller performance but still not as fast as the kit propeller. Team Girl Power were refining their propeller model and getting it ready for fabrication.

-

All the teams identify the wiring modifications needed to the SeaPerch control box so that power would be supplied to the "Brown" wire set for SeaPerch enhancements.

-

LED lights were added to the SeaPerch as an enhancement.

-

Tasks for next engineering session:

-

1. Review the Internship notes - How it Works (it's on the web site in the curriculum section)

-

2. Send in your propeller designs for evaluation and guidance.

-

-

Fri July 27 2012: Propeller Design Review

-

All the teams completed the fabrication of their propeller designs.

-

We conducted a review of the Technical Evaluation process and covered the salient parts of propeller design. The motors that are part of the Sea Perch kit have very little torque. The propeller designs have to be evaluated for the right balance of the diameter, the Solidity Factor Ratio of assumed 2-D rotor blade area / disk area and blade pitch to be used.

-

Tasks for next engineering session:

1. Review the Internship notes - How it Works (it's on the web site in the curriculum section). Write and email your concepts of how the Attributes of Success would help anyone achieve their goals. Please write a few sentences for each attribute.

-

2. Send in your propeller designs for final fabrication.

-

Fri Aug 3 2012: Final Propeller Design Review

-

All the teams completed the fabrication and verified their propeller designs.

-

We conducted a review of the Project Management process and covered the elements to optimize the propeller design for the motor provided with the kit. As a group we talked about the concepts of how the Attributes of Success would help anyone achieve their goals.

-

Tasks for the final engineering session:

-

Fri Aug 10 2012 we will be meeting at Lyman High School Pool area. We will have the final evaluation of our propeller designs. The Teams will participate in races and tasks to evaluate the designs for speed, carrying capability and maneuverability.

-

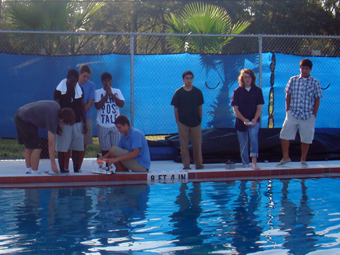

Fri Aug 10 2012: Final Propeller Verification

-

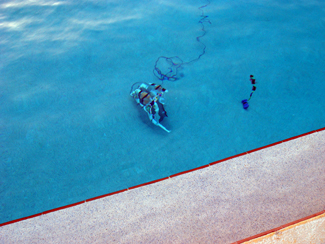

All the teams successfully verified their propeller designs.

-

We met at the Lyman High School Pool area for the final evaluation of our propeller designs. Each team participated in a race and tasks to evaluate the designs for speed, carrying capability and maneuverability.

-

The teams had to race their Sea Perch across the pool. Then dive to retrieve 3 items from the pool floor. Team Deep Blue had the best results by completing the event in 4 minutes 37 seconds.

-

Matrix from our internship:

The teams designed, fabricated and verified 17 propeller designs.

The final propeller designs were very comparable to the propeller that was part of the kit.

The kit propeller was optimized for the low torque motors that were part of the kit. -

We started with 14 students and had 100% retention.

All the learning objectives were met.

All of the participating students will be receiving their certificates, internship and community service hours for their effort.

-

Wed Sep 5 2012: Certification Award Ceremony

-

All the students successfully completed their internship and received their certificates and trophies. The students earned 75 hours for community service / internship.

-

The award ceremony was attended by our special guest Mr Pete Marion, Assistant Program Executive Officer for Customer Support (retired). Mr Marion was one of our key advocates that made this engineering internship come to fruition.

-

In attendance were also the mentors, teacher, family and friends. Their continued support is much appreciated.

|

|

|

|

|

|

|

|

|

|